Nylon PA11

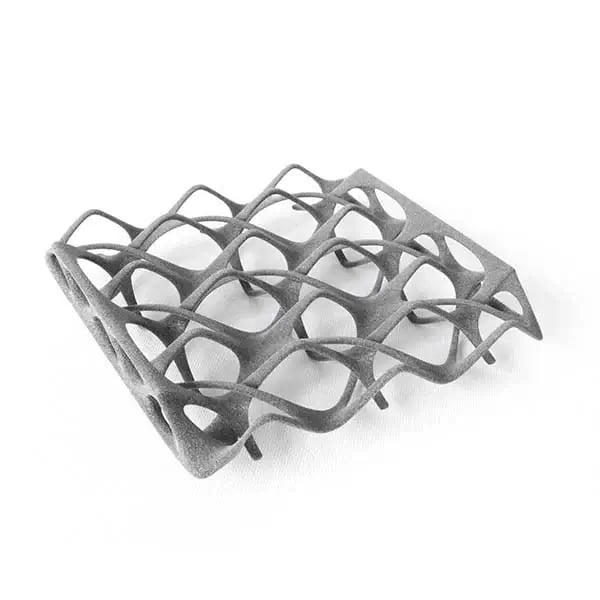

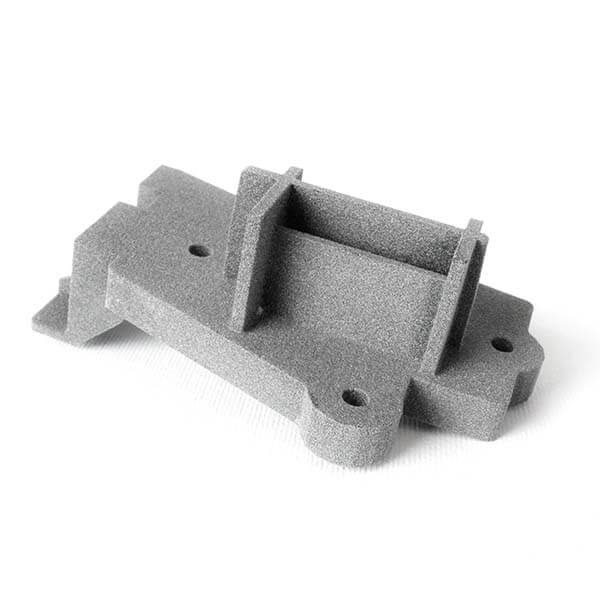

Material showcase

Description

Nylon PA11 is a superior engineering thermoplastic that offers unparalleled performance across a wide range of applications, from industrial settings to specialized equipment. Its mechanical properties boast not only exceptional flexibility and impact resistance, outperforming PA12, but also remarkable strength, durability, and resistance to vibrations and heavy impacts. In addition to its mechanical prowess, PA11 stands out for its excellent wear and abrasion resistance, low friction properties, and high resistance to a variety of chemicals, including acids, alkalis, and solvents. This makes it an ideal material for applications demanding superior chemical resistance and durability.

What sets PA11 further apart from other engineering thermoplastics is its environmental credentials; it is a bio-based material derived from renewable resources like castor oil and sugarcane, offering an eco-friendly alternative without compromising on performance. Even in terms of heat resistance, PA11 can withstand temperatures up to 250°C for limited periods, and its lightweight nature makes it a prime choice for applications where weight is a critical factor.

Overall, for manufacturers seeking a reliable, high-performance, and sustainable thermoplastic, nylon PA11 emerges as an excellent choice, excelling in mechanical strength, chemical resistance, and environmental sustainability.

Pros

Pros

Eco-Friendly

One of the distinguishing features of nylon PA11 is its environmental sustainability. Unlike traditional thermoplastics, PA11 is a bio-based material derived from renewable resources like castor oil and sugarcane. This makes it an eco-friendly alternative that does not compromise on performance, aligning with increasing global emphasis on sustainability.

Superior Mechanical Properties

Nylon PA11 excels in mechanical strength and durability, making it highly resistant to impacts and vibrations. Its unique blend of flexibility and toughness allows it to outperform other engineering thermoplastics like PA12 in various applications. These mechanical advantages make it an ideal material for industries requiring components that can withstand heavy-duty use.

Chemical Resistance

This engineering thermoplastic boasts a high level of resistance to a wide range of chemicals, including acids, alkalis, and solvents. Its chemical resilience makes it an excellent choice for applications that need to withstand corrosive or aggressive chemical environments, thereby expanding its range of utility in specialized and industrial settings.

Cons

Cons

A Little Hygroscopic

It has a tendency to absorb moisture from the environment. This characteristic could still affect its mechanical properties or dimensional stability in humid conditions.

More Expensive than PA12

It comes at a higher price point compared to PA12. This can be a significant factor for manufacturers who are cost-sensitive or are operating on tight budgets. The enhanced performance and sustainability features of PA11 need to be weighed against its higher cost to determine if it is the most suitable material for a given application.

Properties

50 MPa

Tensile breaking load

2000 MPa

Modulus of elasticity

15%

Elongation at break

1730 MPa

Flexural modulus

175°C

HDT 0.45 MPa

3.5 kJ/m²

Izod impact resistance